North America’s Precision Hydraulic Repair Specialists

Specializing in High-Tonnage Cylinders, Pumps, and Rams for Heavy Civil, recycling, and maritime.

630-492-6827

call now for a free quote

sterig hydraulic repairs inc & machining nationwide.

Your Machinery matters to you, and with partnership to Sterig Hydraulics Repair INC, it matters to us!

Hydraulic repair is vital for keeping machinery with hydraulic systems efficient and prolonging its lifespan. Key parts involved in hydraulic repair include cylinders, pumps, and valves. Each component plays a critical role in ensuring proper function, requiring skilled repair and maintenance to avoid failures and maintain performance.

24/7 emergency repair services

hydraulic services

-

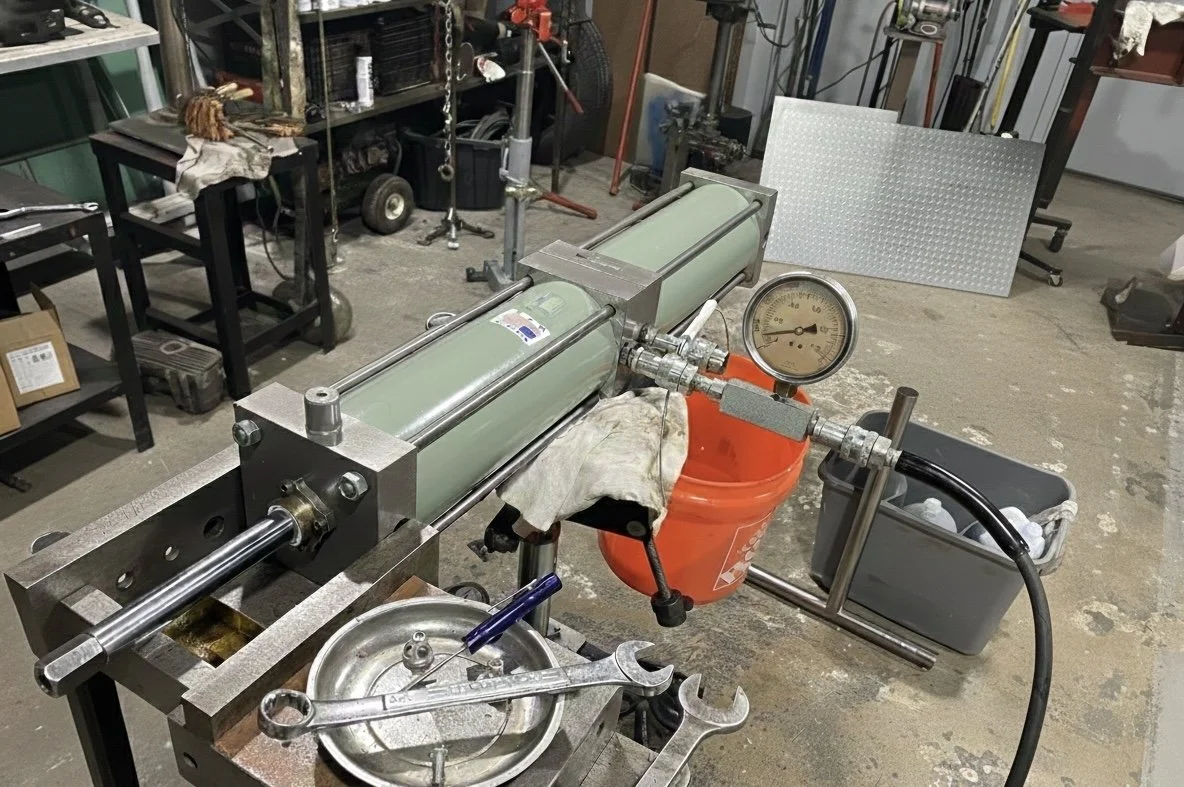

Hydraulic Cylinder Honing & Resealing

We specialize in repairing all types of hydraulic cylinders, Cat, Komatsu, Volvo Sennebogen. Ensuring optimal performance and extended equipment life.

-

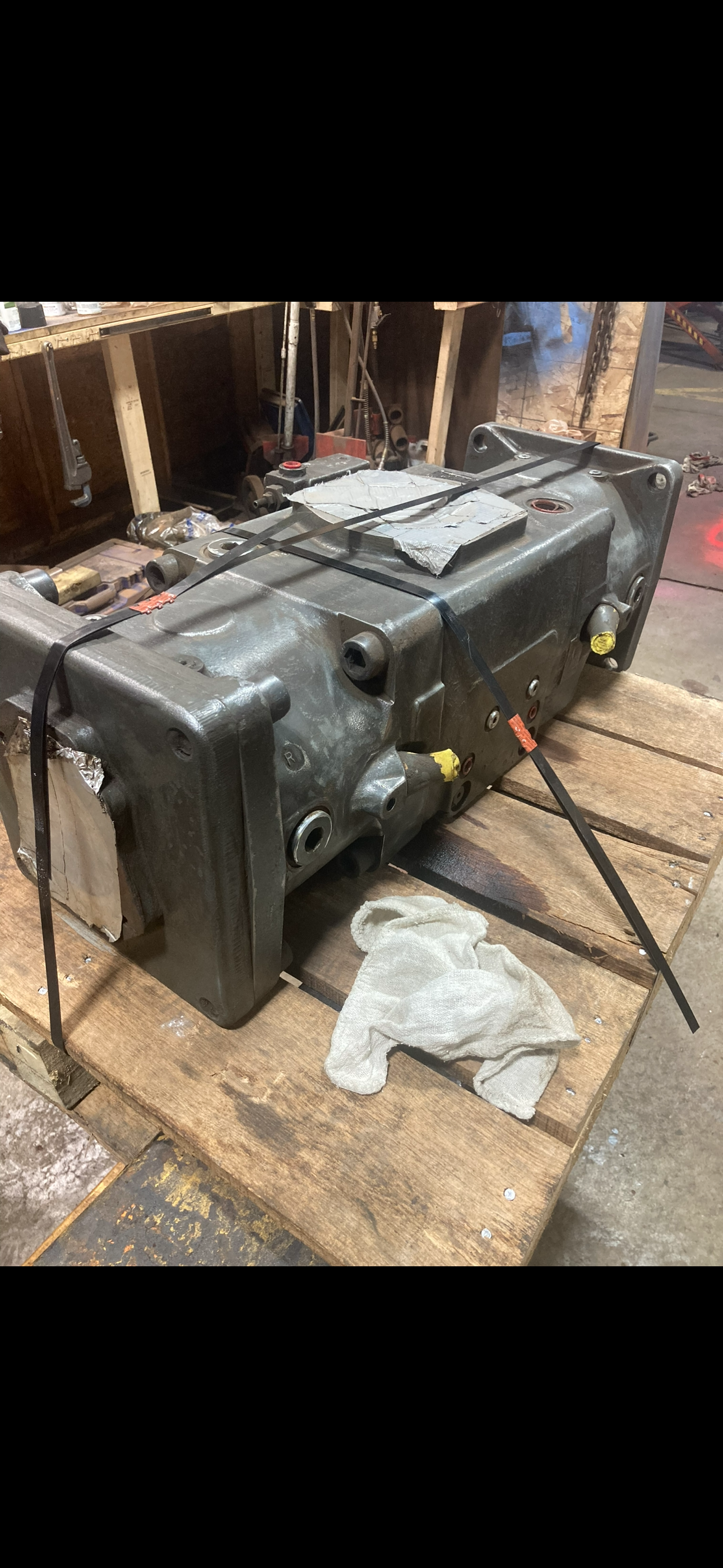

High-Pressure Pump & Motor Rebuilds

Our team is skilled at diagnosing and repairing hydraulic pumps and motors, from Parker, Eaton, DanFoss, Rexroth

-

Hydraulic Control Valves

We repair all types of mobile spool valves and industrial

-

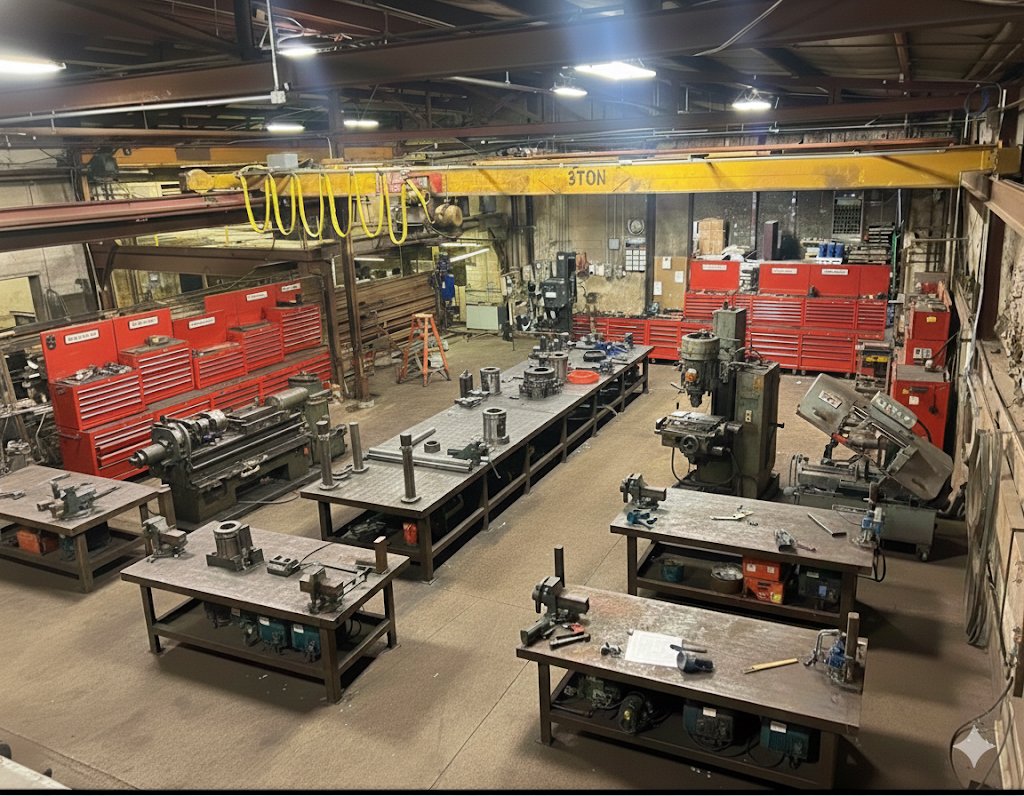

Custom Machining & Rod Straightening

Repair of all types Barrels, Rods, Pistons and welds.

Industries We Support

Construction & Demolition: Built for the Toughest Jobs

In the world of construction and demolition, your hydraulics are under constant pressure. When a cylinder fails on a job site, your entire timeline stops. At Sterig Hydraulic Repair Inc., we specialize in the rapid teardown, inspection, and rebuilding of the high-performance hydraulic systems that power your fleet.

Excavator Hydraulic Repair

The boom, stick, and bucket cylinders on your excavator are the muscles of your operation. We handle everything from minor seal leaks to catastrophic rod damage.

Services: Barrel honing, rod straightening, and custom seal kitting.

Brands We Service: CAT, Komatsu, John Deere, Volvo, and Case.

Components: Main pumps, swing motors, and final drive hydraulics.

Wheel Loader & Backhoe Service

Loaders face high-cycle stress every day. We ensure your steering and lift cylinders are operating at peak pressure to maintain safety and efficiency.

Specialty: We repair steering cylinders, tilt cylinders, and lift arms.

Precision: Every rebuild is pressure-tested to ensure it meets or exceeds OEM specifications before it leaves our shop.

Hydraulic Hammer & Breaker Rebuilds

Demolition hammers take more abuse than almost any other attachment. The internal seals and pistons are subject to extreme heat and vibration.

Expertise: We provide complete resealing and piston polishing for hydraulic breakers.

Performance: Proper maintenance prevents "dry firing" damage and extends the life of your nitrogen-charged systems.

Why Sterig for Construction?

Emergency Turnaround: We know that "downtime is death" for a project. We prioritize construction repairs to get you back in the dirt.

Cost-Effective Alternatives: Don’t pay dealer prices for a new cylinder. We can often machine a custom rod or hone a barrel for a fraction of the cost of a replacement.

Local Expertise: Serving Lake Barrington and the greater Chicagoland area with heavy-duty solutions that last.

Scrap Yard Hydraulics: Heavy-Duty Repairs for Maximum Uptime

Material Handlers: Keeping the Flow Moving

In a scrap yard, your material handler is the lifeline. Whether you’re running a Sennebogen, Fuchs, or Liebherr, we specialize in the high-cycle hydraulic systems that allow these machines to sort and load 24/7.

Boom & Stick Cylinders: We handle large-bore cylinder repairs, including precision honing to remove scoring caused by the abrasive dust of a scrap yard.

Grapple & Magnet Hydraulics: Fast resealing and rod repair for orange-peel grapples and magnetic attachments.

Cab Riser Hydraulics: Specialized service for the hydraulic lifting cabs that give your operators the visibility they need.

Shear & Baler Cylinder Rebuilding

The hydraulic force required to shear structural steel or bale a car is immense. These systems face extreme pressure spikes and side-loading. At Sterig, we don’t just "fix" these cylinders; we engineer them to last longer.

Shear Cylinders: We provide heavy-duty re-chroming and rod straightening for massive guillotine and alligator shears.

Baler Rams: From two-ram balers to car loggers, we service the main compression cylinders that take the most abuse.

Brands We Service: Sierra, Genesis, LaBounty, and Allied.

Why Scrap Yards Trust Sterig Hydraulic Repair Inc.

Downtime is the Enemy: We offer expedited turnaround times because we know a parked machine in a scrap yard is costing you money every hour.

Local Midwest Expertise: Located in Lake Barrington, we are ideally positioned to serve scrap yards across Illinois and the Midwest.

Repair vs. Replace: We specialize in rebuilding components that dealers would tell you to scrap. We save you thousands by restoring your existing iron to OEM specs.

Industrial Hydraulic Solutions: Precision for High-Volume Manufacturing

Industrial Press Cylinder & System Rebuilds

Whether it’s a stamping press, a forging press, or a plastic injection molding machine, your operation depends on consistent, high-pressure force. Even a minor internal bypass in a cylinder can ruin a production run.

Large-Bore Cylinder Specialist: We repair and rebuild the massive cylinders that power heavy industrial presses, ensuring they hold pressure under the most demanding duty cycles.

Precision Honing & Sealing: Our on-site honing restores the mirror finish required for high-pressure seals to function without leaking, extending the life of your equipment.

Manifold & Valve Service: We troubleshoot and repair complex hydraulic manifolds and directional control valves that dictate the timing and safety of your press operations.

Q: What types of hydraulic systems do you repair?

A: We specialize in repairing a wide range of hydraulic systems, including pumps, cylinders, hoses, and valves.

Q: Do you offer emergency repair services?

A: Yes, we provide 24/7 emergency hydraulic repair services to minimize your downtime.

Q: How can I request a service?

A: You can call us directly or use our online service request form.

Q: What brands do you work with?

A: We repair major hydraulic brands including Caterpillar, John Deere, Komatsu, Bosch Rexroth, Eaton, and Parker.

Can a bent hydraulic cylinder rod be fixed?

A: Yes, most bent hydraulic rods can be straightened using a high-tonnage hydraulic press and precision measuring tools. If the rod is bent beyond the safety limit or the chrome is cracked, Sterig can machine a custom replacement rod in-house using induction-hardened chrome material to get your machine back in service without the long lead times of OEM ordering.

Q: How long does a hydraulic pump or motor rebuild take?

A: A standard hydraulic pump rebuild typically takes 2 to 5 business days, depending on parts availability. However, for critical "machine down" situations in the Chicago and Lake Barrington areas, Sterig Hydraulic Repair Inc. offers expedited service to minimize downtime for construction and scrap metal operations.

Q: Why is my excavator cylinder leaking after a seal change?

A: If a cylinder leaks shortly after a seal change, the issue is likely barrel scoring or a nicked rod. Even microscopic scratches can shred new seals. At Sterig, we use precision honing to smooth the internal barrel surface and inspect rods for "pitting" to ensure a leak-free seal that lasts.

Q: Is it better to repair or replace a hydraulic cylinder?

A: In 90% of cases, repairing a hydraulic cylinder is more cost-effective than replacement. A professional rebuild at Sterig Hydraulic Repair Inc. typically costs 40-60% less than a new OEM unit. Rebuilding also allows for custom upgrades, such as high-performance seals and precision honing, which can make the repaired cylinder more durable than the original.